PRODUCT CATEGORIES

-

power plant stacks chimney

power plant stacks chimney

-

Pulp & Paper stacks chimneys

Pulp & Paper stacks chimneys

-

Petrochemicals stacks chimneys

Petrochemicals stacks chimneys

-

Chemicals Refinery stacks chimneys

Chemicals Refinery stacks chimneys

-

Reclining industry stacks chimneys

Reclining industry stacks chimneys

-

Food & Beverage stacks chimneys

Food & Beverage stacks chimneys

-

Cement & Lime stacks chimneys

Cement & Lime stacks chimneys

-

Mining & Minerals stacks chimneys

Mining & Minerals stacks chimneys

-

Steel & Metal stacks chimneys

Steel & Metal stacks chimneys

-

Chimney stacks Decoration

Chimney stacks Decoration

-

Thin Wall Titanium Clad Steel Plate

Thin Wall Titanium Clad Steel Plate

-

Stove Fireplace Chimney

Stove Fireplace Chimney

-

Chimney stacks accessories

Chimney stacks accessories

LATEST NEWS

CONTACT US

Tel:+86 (028)-62561606

Fax :+86 (028)-62561733

Mobile:+86 15881040688

Email: [email protected]

Whatsapp: +86 15881040688

TOP 5 MATERIALS FOR CHIMNEYS, OR WHICH CHIMNEY TO CHOOSE

Article content

By: YB chimney www.industrychimney.net orignal link: https://ybchimney.blogspot.com/2022/03/top-5-materials-for-chimneys-or-which.html

The main function of the chimney is to remove the combustion products from the furnace to the outside, but its role in the combustion of fuel and draft formation cannot be underestimated. Experts say that with the right choice of materials for chimneys and proper installation, the heat transfer of furnaces or boilers can increase by 10-15%. However for gas or solid fuel boilers, fireplaces and stoves will need a chimney of not only different heights and diameters, but also materials. If previously you only chose between brick and non-galvanized metal then today, the range of suitable options is much wider. We figure out which materials for chimneys, more precisely chimneys, exist, for the conditions under which they intend and which chimneys to choose depending on the type of fuel used..

WHAT TO CONSIDER WHEN CHOOSING A MATERIAL FOR CHIMNEYS?

Complex construction chimneys include a vertical tube, an umbrella for rain protection, viewing windows for maintenance, a drip tray for collecting condensed water and other elements. The vertical tube is considered the main part of the chimney, and the safety and effectiveness of operation depends on it. oven or boiler.

To choose the right chimney material, you must clearly understand which fuel will be used: natural gas, diesel fuel, coal, firewood, peat or sawdust. Each of them has different combustion temperatures, temperatures and components of emissions. Therefore, when choosing materials for chimneys, such parameters are taken into account:

emission temperature. Naturally, the material must withstand a slightly higher temperature than the characteristics of the outgoing gas;

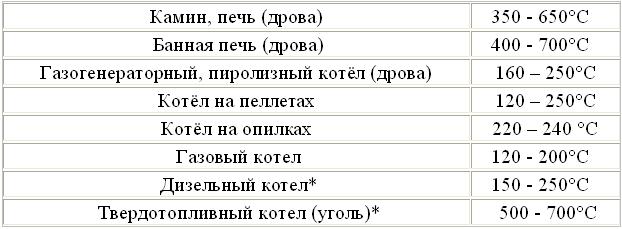

Estimated emission temperature (* high sulfur fuel)

corrosion resistance. When certain fuels are burned, sulphuric vapor and hydrochloric acid are formed, which not all materials tolerate. The more sulfur in the fuel composition, the more likely it is to resist the effects of sulfur compounds that should be the material. According to this parameter, the chimney divides into three layers: first - for the removal of gas-fired products, the second - firewood and liquid fuel with a sulfur content of up to 0.2%, the third - for coal, peat, diesel fuel;

the presence of condensation in the chimney;

gas pressure in the chimney. There are designs designed to operate under natural traction, and there are designs designed to work with supercharged boilers;

soot fire resistance. The temperature in the chimney when burning soot, if any, can rise rapidly to 10000C - not every material is bearable.

From all this, it follows:

for wood stoves, solid fuel boilers, stoves and fireplaces need to choose materials that withstand operating temperatures of about 7000C and increase short-term to 10000C. These are brick chimneys and less often;

For gas boilers requires a chimney that can withstand temperatures of 2000C with a short-term increase to 4000C. Usually metal pipes are used for this purpose;

For liquid fuel boilers and sawdust you need such material for a chimney that can easily withstand temperatures of up to 2500C up to 4000C, and when it comes to diesel fuel, it also tolerates the hostile environment of emissions.

We will now understand the properties of the most common materials used to equip the chimney.

NO. 1 BRICK CHIMNEY

Bricks for the installation of chimneys have been used for a long time, and it has become a traditional material. Today, it cannot be called universal, however, that does not reduce its popularity. Brick chimneys fitted inside the walls of the building, sections that pass through unused rooms or outside the building, carefully insulate so that the exhaust does not cool inside. To arrange such a chimney is suitable solid brick red point not lower than M150, for the use of its masonry lime or mortar cement lime.

The main advantages of brick pipes for chimneys, their durability and excellent heat resistance (ceramic tiles withstand temperatures up to 8000C), and in terms of appearance they look great, and in terms of fire safety, they are practically second to none. The brick chimney is suitable for stoves and fireplaces on wood, and when working with boilers for liquid fuel, gas, pellets and heat boilers with solid fuel, it quickly collapses. The thing is that such boilers are designed in such a way that emissions have low temperatures. They quickly condense and stabilize on the walls of the pipe, so are then constantly moistened. Given the fact that gas contains powerful chemicals, including sulfuric acid, bricks quickly collapse. The result of this effect is manifested by wet spots on the outer surface of the pipe.

Yes, there is always a way out of the situation. To connect a modern gas or fuel boiler to a brick chimney, a steel-dipped brick channel or a ceramic pipe has slightly different performance.

Since the surface of the brick is rough, soot settles well on it, gradually leading to a decrease in traction. Cleaning and repairing a brick pipe is not an easy task. In addition, the large weight of the structure will necessarily have a foundation. On the other hand, it is difficult to find a worthy analogy to arrange a chimney of the stove or fireplace.

NO. 2 STEEL PIPE CHIMNEY

For gas boilers and solid fuel steel pipes are the most suitable, but it should be stainless, heat resistant and acid resistant, since sulfur particles, present in almost any type of fuel in one or another, when combined with coal particles and moisture form an aggressive environment. Stainless steel is capable. It can withstand temperatures of up to 500.0With, pipes with a thickness of 0.6 mm are used for chimneys, but for solid fuel boilers it is better to use 1 mm thick steel. Steel pipes represent both a system of straight sections and various shape elements, including adapters, bends, Tees, etc. Such a system can be independently mounted or built into an existing brick channel.

The main advantages of steel pipes:

simplicity and high installation speed, since the weight of the structure is small, without the need for foundation and finished elements, not even the largest specialist will assemble the entire system without problems;

Repair work is not difficult;

Soot particles do not accumulate on smooth walls, their surface is easy to clean, so we can talk about the constant high aerodynamic properties for emission escape;

high corrosion resistance;

the ability to create complex structures;

high tightness, so you can create a mandatory hood.

Among the disadvantages They call it a high cost, especially when compared to a brick or ceramic analogue, but if the simplicity and speed of arrangement, light weight and resistance to the invasive environment are important, then it is better to stop the option on the steel chimney. The disadvantages are sometimes attributed to low heat resistance, but for modern boilers with slow combustion systems, greater heat resistance is not necessary.

Depending on the characteristics of the room, boiler and climate, use one of the following types of steel chimneys:

Single steel pipe consists of a layer of stainless steel. This is the easiest and cheapest option, they put such a chimney in a specially placed vertical channel. Often the same chimney fitted in the bathtub, and the heat leaves the steel pipe used to heat the water;

Single-walled steel pipes to rebuild a brick chimney can be oval-shaped. The process of recovery and adaptation of an existing chimney to work with a gas boiler is called the sleeve tube;

two-wall sandwich plates, consisting of two steel pipes, in the space place an insulation layer (basalt wool). Using the latter allows you to prevent the formation of condensation inside the pipe, while its outer surface is hardly heated. Easy assembly and excellent performance allow the use of such systems both indoors and outdoors on the walls;

Coaxial Steel Chimney They also consist of two tubes placed another tube, only there is no insulation between them and the resulting space is designed to provide air to the boiler to maintain the combustion process. Combustion products are discharged through the internal pipe. Such chimneys do not work very well in the harsh winter conditions in the water. The cold air outside that passes through the outer pipe can sometimes cool the inner pipe and the gas flows through it. This leads to a sharp loss of condensed water and freezing on the surface of the pipe. The chimney gradually becomes clogged, and the automation, which meets this, turns off the boiler, so in this case it is better to equip the chimney with two separate tubes.

It is worth noting that sometimes thick tubes made of low alloy steel are used to equip chimneys - this option is often found in stoves. In addition, craftsmen sometimes use for the same purpose. cast iron sewer pipe.

NUMBER 3. CERAMIC CHIMNEY

Ceramic pipes for chimneys are considered the most common, and among them the main advantages:

Durability

against invasive and corrosive environments;

soot does not linger on a smooth inner surface, making it easier to maintain the pipe;

high heat absorption properties;

resistant to high temperatures. For solid fuel boilers, the ceramic pipe used can withstand up to 6500C and withstands a sharp rise in temperature when soot burns. For gas boilers, up to 450 resistant pipes can be used.0C, designed to work in a humid state and have steam traps.

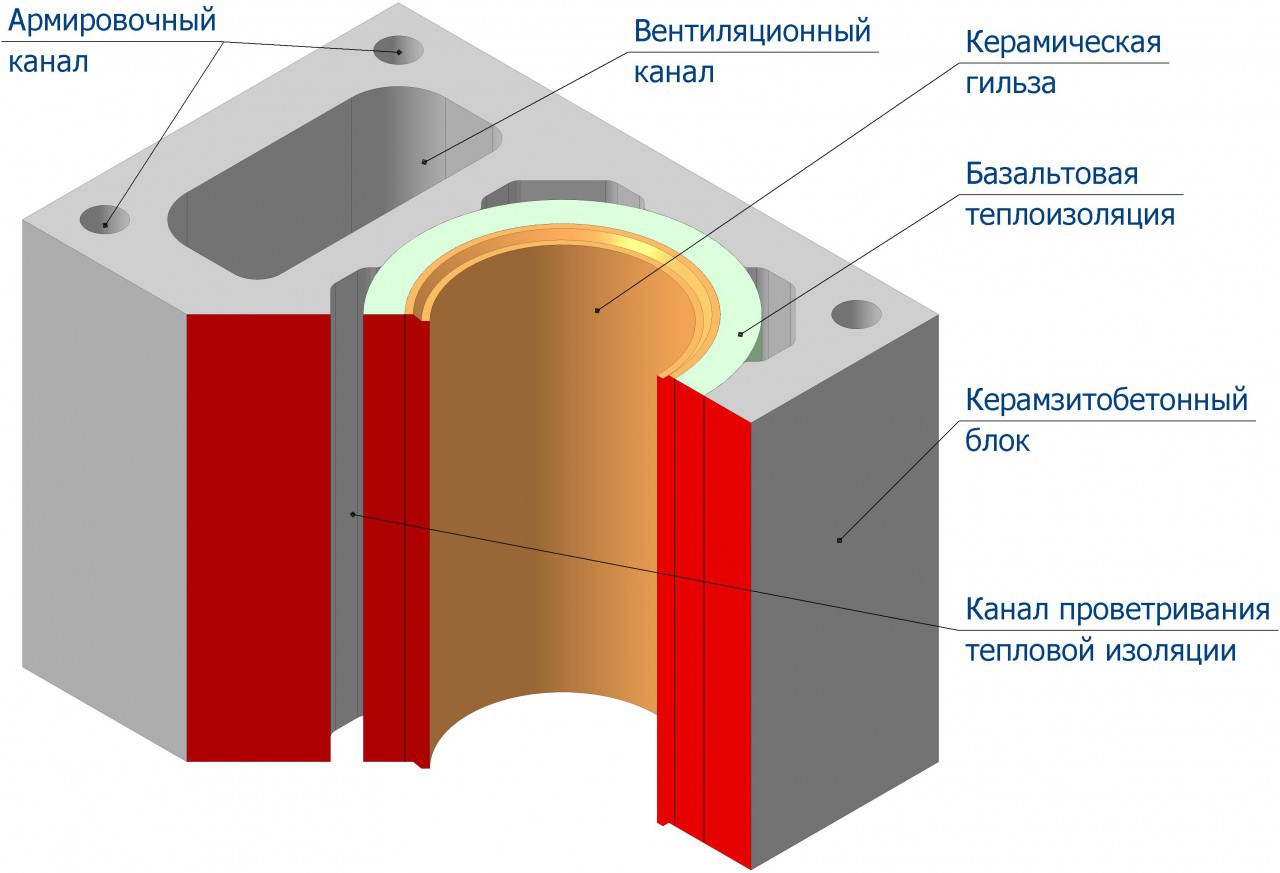

To install ceramic chimneys, it is necessary to have a separate channel. The shell is specially equipped with concrete blocks with gaps. A layer of mineral wool insulation is placed around the pipe to protect neighboring structures from excessive heat and reduce condensation. Both pipes and insulation can draw water, so they need to ensure normal ventilation. It is created due to the presence of vertical air channels between insulation and concrete blocks. By the way, in concrete blocks there are also channels for placing reinforcement in it. Be sure to reinforce the part of the chimney facing the street.

To expand the range of use of ceramic chimneys, they are produced in the case of steel as well as rectangular elements. The former does not require the arrangement of the foundation and creates special channels, the latter can be used to reconstruct the brick chimneys.

NUMBER 4. CHIMNEY FROM ASBESTOS CEMENT PIPE

A few decades ago, asbestos cement pipes were commonly used to equip chimneys. In fact, they were not originally intended for such a purpose, which can be easily verified by studying their operational qualities. Among the advantages of the material, only its low price, and here the disadvantage is much more.

materials that withstand temperatures up to 3000C, and often this is not enough. It is possible to use only such a pipe at the maximum distance from the furnace, where the smoke passing through has been cooled;

soot quickly accumulates on a rough surface, which tends to catch fire. But if a brick chimney can easily cope with this, then the chimney from an asbestos cement pipe can simply explode;

instability before condensation, which contains strong chemicals. Moreover, condensation can be absorbed into the pipe, destroying it and worsening the appearance;

heavy weight and difficult installation;

It is only possible to use asbestos cement pipes for chimneys if you are sure that the installation will be carried out correctly, and also must be regularly cleaned of the chimney, but it is better to pay attention to other options.

NO. 5 VERMICULITE TUBE FOR CHIMNEY

Not so long ago, vermiculite chimneys appeared for sale. These are stainless steel tubes that are coated inside a layer of vermiculite minerals 5 cm thick. This mineral has low thermal conductivity, so, in fact, it is a natural insulator. Moreover, vermiculite is completely inert with strong combustion products.

Among others the benefits of high-strength vermiculite pipes, which are relatively easy to install, do not need the insulation of the chimney. The main disadvantage lies in the ability to accumulate soot, so you will have to regularly clean the chimney.

OTHER OPTIONS

Currently, there are many other ways to equip chimneys:

Glass pipes a few years ago they might have been confused, but today their advantages are undeniable. Glass does not accumulate soot and soot, is easy to clean, inert to the invasive environment and can withstand high temperatures. But a glass chimney will be very expensive, it is difficult to equip it, will need more insulation and the sealing of the joints is very complicated, therefore, until such an extravagant method is not distributed;

polymer tube - another novelty. They are made from mixtures that, according to the claimed qualities, have a long service life, but can only be used at an exhaust temperature of no more than 250.0C, i.e. its range is limited geysers and boilers;

Concrete blocks and chimneys poured from concrete in some sources are called a brick pipe replacement. Experts strongly criticized this option and advised against playing with fire: concrete will not withstand severe temperature loads, and it is impossible to create a heat-resistant preparation at home.

Finally, we note that before choosing the material for the chimney, you must choose the boiler or determine the design of the furnace. In addition, it is worth considering the design features of the building, and it is best to consider all the nuances of its future heating before starting the construction of the house. The calculation of the chimney channel for your safety is best left to a specialist.